|

| |

|

• Services Dienstleistungspalette (Deutsch) Servicios (Español) Services (Français) Chi siamo (Italiano) Serviços (Português) • About Scientific Advisory Services, Ltd. • Curriculum Vitae Dr. C. J. Abraham • What Effect Does Protective Headgear Have on Reducing the Impact to the Brain in Soccer and All Other Sports? [PDF] • New Materials Award of the Textile Institute • Amusement Park Accident Verdict • Overcoming Federal Preemption • Playground Safety • Playgrounds and Amusement Parks • Concussions - Your Body Is Nothing Without A Brain [PDF] • Prior Trial Results • Human Factors, Safety & Hazard Analysis • Toy Design & Safety • Warnings & Instructions • Sports & Recreation Safety • OSHA and Labor Law • Slips, Trips & Falls • Recreation & Sports Accidents • Columbia University Presentation • The Flammable Fabrics Act: An Unreasonably Dangerous Act • Flammable Fabrics Case • A New Standard of Care in Absorbing and Dissipating Forces • A Viable Product vs. The Legal System • Concussions, Head Injuries and the Textile Industry [PDF] • Concussions and Potential Risks in Children and Adults [PDF] • United States District Court Decision: Allison Nowak, et al Plaintiffs v. Faberge U.S.A. and Precision Valve Corporation, Defendants • Arnau v. WC Maui Coast LLC, et al.; U.S. District Court, District of Mawaii • Industrial Products & Equipment • Improved Protection For Sports Helmets • News – Battery Petition • NHTSA Petition: Battery Explosions • Soccer – Head Injuries and Protection • National Alliance for Youth Sports – SportingKid Magazine – Fall 2007 • Dr. Abraham at Columbia University [PDF] • ForceField FF Headbands • Contact Information |

Dr. Abraham has created and pioneered an innovative approach for evaluating the adequacy and communication effectiveness of the warning and instructional materials associated with any product.

This activity is directed by Dr. Abraham who uses his thirty years of international experience in industry, new product development, human factors, OSHA, safety, voluntary standards, statutes, labeling, custom and practice, technology and cost in relationship to the hazards, dangers and risks involved in the use and application of the product(s). He has created and critiqued warnings and instructions for a large variety of products and standards used throughout the world.

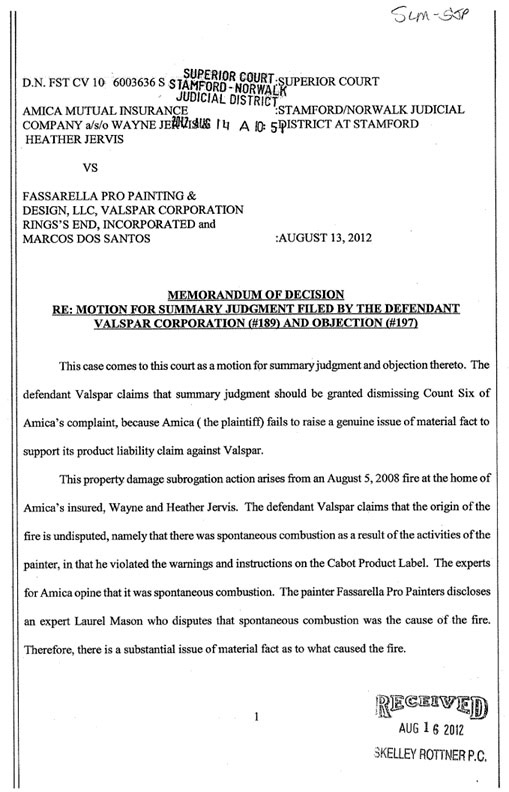

For the first time, Dr. C. J. Abraham's argument and affidavit was able to overcome Valspar Corporation's claim for federal preemption.

Tool post grinder lacked adequate instructions, leading to wheel's explosive failure. Calabria v. Dumore Corp., N.Y., Bronx Co. Sup., No. 305524/08, Apr. 4, 2011. Ludovico Calabria, a 57-year-old machinist, assembled a tool post grinder for his employer's machine shop. The grinder, which is used to shape and finish machine parts, is powered by a lathe spindle and can he fitted with a customized metal wheel. Calabria inadvertently installed the wheel with its sides facing the wrong way. When he turned the grinder on to test it, the wheel exploded, striking him. He suffered a fracture to his left, nondominant arm, which required open reduction and internal fixation with a rod and screws. His past medical expenses totaled about $43,360, and he will incur future medical expenses of an unspecified amount. Although Calabria returned to work about 10 months after the incident, he continues to suffer from pain and a restricted range of motion in his arm, and he is unable to lift heavy objects. He incurred about $22,900 in past lost earnings. Calabria sued the manufacturer of the grinder, alleging that it lacked adequate instructions on proper assembly of the grinder post spindle and wheel. Specifically, the plaintiff contended that the spindle could be put into the grinder in two different ways, and the warnings were not clear as to which way the spindle should be mounted. The plaintiff asserted that if the spindle was mounted backwards, as it was here, the flanges on each side of the wheel would be different diameters, creating pressure on the wheel and causing it to fail. The plaintiff also sued the manufacturer of the wheel, alleging that it failed because of an impurity created during the manufacturing process. Specifically, the plaintiff contended that the wheel was adulterated with metallic flakes, so that it lacked adequate integrity and exploded when it was powered up. The wheel manufacturer denied there was an impurity and argued that no metallic flakes could have existed because the wheel was heated to high temperatures in a kiln during the manufacturing process. The defendant also argued that any flakes that may have appeared after the incident were introduced when the wheel exploded and struck a wall. The grinder manufacturer argued that its instructions were adequate. In addition, both defendants contended that Calabria was negligent in assembling the spindle backwards and that he had misused the grinder by doubling its recommended operating speed of 4,000 revolutions per minute, causing it to explode. The parties settled for $745,000. The grinder manufacturer paid $700,000. and the wheel manufacturer paid $45,000. There is a net workers' compensation lien of about $44,200. The plaintiff's expert was Carl Abraham, warnings, Great Neck, N,Y. The defendant's expert was Roy Kulick, orthopedics, New York, N.Y.

Plaintiffs Counsel

| |